Simply claiming products are “green,” “ecologically-friendly,” or “sustainable” is no longer good enough. Overused words, phrases, and claims such as these often become meaningless. This has paved the way for Life Cycle Assessment (LCA).

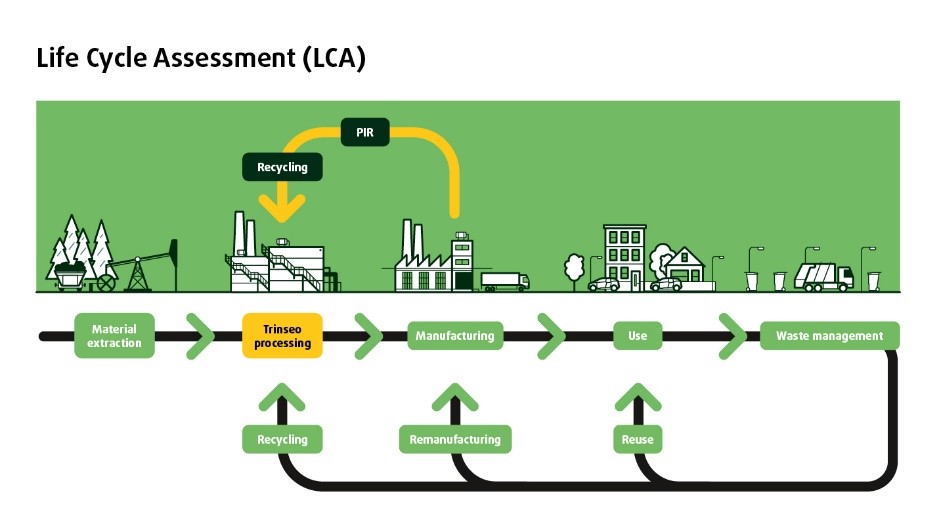

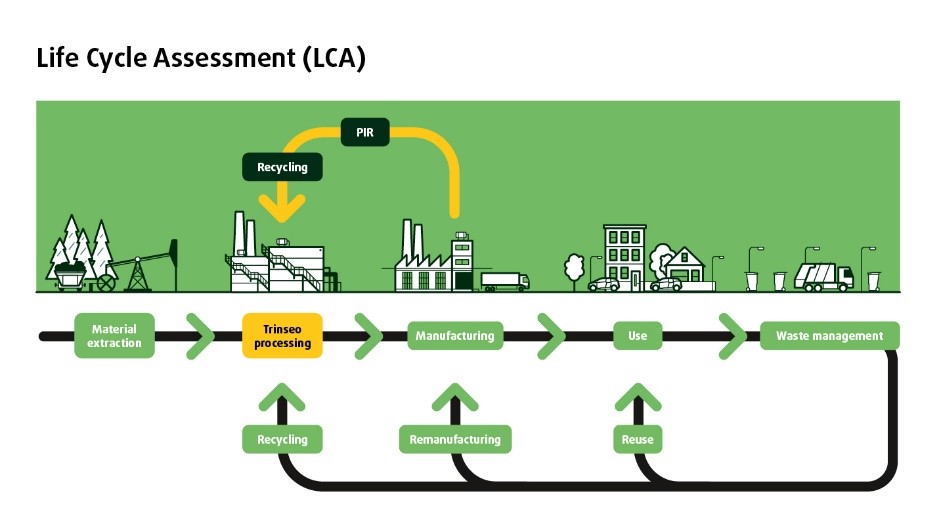

LCA is a methodology used to provide evidence. By identifying the sustainability targets we hope to achieve and then determining how a product and its manufacturing process impacts that target, we are able to develop quantifiable, supporting data to validate our claims.

LCA is used across industry sectors, particularly in Automotive and Consumer Electronics. These industries can significantly improve their impact on the environment and/or have consumer pressure to address sustainability concerns.

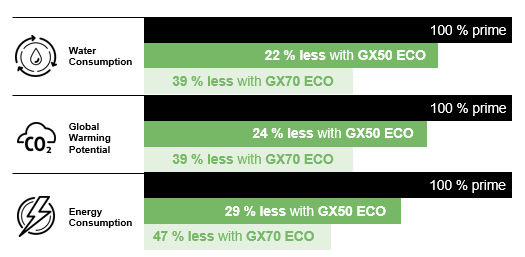

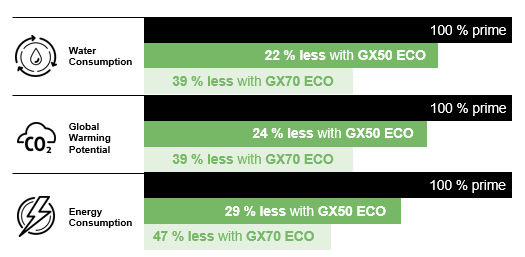

According to Trinseo’s Frank Schumann, Global Marketing Manager, Automotive, the top sustainability concerns globally are to avoid global warming, and also the depletion of our natural resources, namely water and energy. Acceptable metrics to measure these targets are: CO2 emissions released and water and energy consumed.

These sustainability concerns can be expanded, he adds, to include other areas that influence human life such as land use, deforestation, child labor, or impact on the food supply. After all, the definition of sustainability is broad -- to meet the needs of the present without compromising the ability of future generations to meet their own needs – and the ramification of our actions and the impact of the products we create are often far reaching.

A Process Flow Starts It All

Wherever the starting point, the key is to build a process flow and measure each step in the production process. This will include the raw materials, how they were extracted, transportation, and the natural resources consumed during the manufacturing process.

It will also include the analysis of the output, or the final product. What becomes of it? Will it go into a larger product or application? Does the final product or application have an impact on our sustainability goals?

A simple example of LCA, and one that Trinseo is involved with all the time, is to determine the sustainability impact of replacing a traditional ingredient with a sustainable alternative. Trinseo did this when it introduced a sustainable alternative to the PULSE™ GX Series of resins, which is manufactured with a combination of petroleum-based polycarbonate and Acrylonitrile Butadiene Styrene (ABS.)

The alternative, our PULSE™ ECO grades, replace the polycarbonate portion with post-industrial recycled (PIR) polycarbonate, i.e., a material that had already been manufactured, was considered scrap, and was reclaimed from an industrial setting. Using LCA, we were able to quantify the CO2 emissions saved in the PIR / polycarbonate portion, since CO2 had been emitted when the material was initially processed. Other parameters that influence the LCA results are water and energy savings, emissions associated with the transportation of the goods to the manufacturing facility and even the benefits from using a lighter material in the final application.

One can see that an LCA process can be complex and multifaceted. The data required to conduct the analysis is not always readily available and sometimes a process needs to be put in place to collect it. While it can be done internally, an objective third party is often chosen to conduct the analysis.

According to Schumann, Trinseo collaborated with a university in Germany to conduct LCA on its polycarbonate plant in Stade, Germany to certify the sustainability claims regarding its operations. This required an analysis of various criteria involved in the production of 1 kg of polycarbonate, followed by an extrapolation of the data to facility-level production capacity.

Clearly LCA is a growing trend. In most circles, the analysis is not a requirement yet soon companies and customers will undoubtedly ask for it, specifying what thresholds need to be attained, similar to how performance attributes are specified today. Consumers too will be more accustomed to seeing this type of information on their products, like they do, to some extent, on new vehicle stickers.

“It’s all about making a process visible and following the flow of materials and resources used. I like to say we’re demystifying and putting numbers to a great big black box,” said Schumann.

“绿色”、“生态友好”或者“可持续”等宣传用语在市场上已司空见惯,而空喊这些陈词滥调其实没有什么意义。于是,生命周期评估 (LCA) 应运而生。

LCA 可用于提供证据。我们可以通过确定我们希望实现的可持续性目标,以及产品及其制造流程将如何影响该目标,来获得可量化的支持性数据,从而证实我们的可持续性声明的真实性。

LCA 广泛用于各个行业领域,尤其是汽车和消费电子产品领域。这些行业可以显着改善其对环境的影响和/或在来自消费者方面的压力之下解决可持续性相关的问题。

盛禧奥汽车业务全球营销经理 Frank Schumann 表示,全球最受关注的可持续性问题是避免全球变暖以及防止自然资源(即水和能源)枯竭。用于衡量上述目标的可接受指标为:二氧化碳的排放量以及水和能源的消耗量。

他补充道,这些可持续性问题还可以进一步延伸到影响人类生活的其他领域,例如土地使用、森林砍伐、童工或对食品供应的影响。毕竟,可持续性的定义很宽泛——既要满足当代人的需求,也不能损害子孙后代满足自身需求的能力——我们行动的后果和我们打造的产品通常会造成深远的影响。

工艺流程是一切的开始

无论起点在何处,关键都在于建立工艺流程并衡量生产过程中的每个步骤。这将涉及原材料本身、原材料的提取和运输以及制造过程中消耗的自然资源。

同时还包括对输出或最终产品的分析。 原材料最终会变成什么?会变成更大的产品或应用吗?最终产品或应用是否会对我们的可持续发展目标产生影响?

LCA 的一个简单示例(同时也是盛禧奥一直都在做的一件事)就是确定用可持续替代品代替传统成分在可持续发展方面产生的影响。盛禧奥在推出 PULSE™ GX 系列树脂的可持续替代品时开展了这项工作,该系列树脂由石油基聚碳酸酯和丙烯腈-丁二烯-苯乙烯 (ABS) 结合而成。

盛禧奥推出的替代产品,即 PULSE™ ECO 系列产品,用后工业回收(简称 PIR,即已制造完成的材料被认为是废料,并且在工业环境中被回收)聚碳酸酯替代了聚碳酸酯部分。我们能够通过 LCA 量化由 PIR/聚碳酸酯部分减少的 CO2 排放量,因为在最初的材料处理过程中就已经产生了 CO2 排放。影响 LCA 结果的其他参数包括节水和节能、将货物运输到制造工厂所产生的排放,甚至在最终应用中使用较轻的材料所带来的益处。

可以看到,LCA 流程可能非常复杂并且涉及多个方面。开展分析所需的数据并不总是现成的,有时需要建立适当的流程来收集所需数据。尽管分析可以在内部完成,但常见的做法是选择客观的第三方来完成。

据 Schumann 所说,盛禧奥与德国一所大学合作,对其位于德国施塔德的聚碳酸酯工厂进行 LCA,以证明其运营的可持续性。这就需要分析生产 1 公斤聚碳酸酯所涉及的各种标准,然后将数据外推到工厂规模的产能。

显然,LCA 是一个发展趋势。在大多数情况下,分析并不是必需的,但不久的将来,公司和客户一定会提出开展分析的要求,并指定需要达到哪些阈值,就像如今对性能设立指标一样。在某种程度上,消费者也将更习惯于在所购买的产品上看到这类信息,就像他们在新车贴上看到的那样。

“关键在于使流程透明化,并密切跟踪材料流和所用资源。我认为我们正在揭开一张神秘面纱,然后将数字放入一个巨大的黑匣子中,”Schumann 说道。