It was a demonstration of future carbon-negative automotive materials when the technology startup Opus 12 and Daimler showcased the world’s first C-pillar made with polycarbonate (PC) from CO2 electrolysis at the February 2020 “Startup Autobahn” exhibition. Trinseo is very proud that we could contribute to this success with our expertise and PULSE™ GX50 PC/ABS.\

Startups are important partners on the road to the automotive future. They speed up the development of new technologies with their visionary ideas. With the "Startup Autobahn" initiative, the future-oriented German Automotive OEM Daimler has been offering startups a platform since 2016 for jointly sounding out whether and how their visions are suitable for series production.

Currently, the theme of the initiative's scouting is "The Next Green Thing". Daimler is looking for initiatives that provide sustainable solutions to reduce the OEM’s environmental footprint and support its ambitious 2039 goal towards an entirely carbon-neutral vehicle fleet.

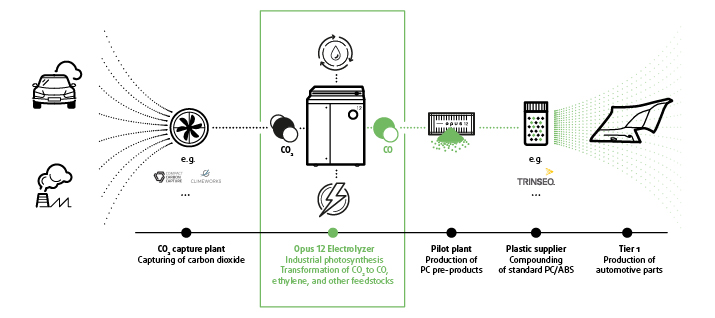

One of the startups that Daimler has teamed up with is Opus 12, a company that has developed a device that recycles CO2 into cost-competitive chemicals and fuels by bolting onto CO2.

Daimler contacted Trinseo to assist in producing material samples of PULSE™ GX50 PC/ABS, containing a small portion of PC made by Opus 12. The material was produced at Trinseo’s Technology & Innovation Center in Terneuzen, The Netherlands. The automotive Tier 1 and Trinseo partner, MöllerTech used this material to mold a first carbon-negative Mercedes C-Pillar.

Trinseo has already showcased its expertise in developing sustainably advantaged materials for the automotive industry with the launch of the PULSE™ ECO Series, a portfolio of recycled content-containing PC/ABS.

Our involvement with Opus 12 and Daimler is just the latest example of how innovation is fostered through partnerships. Trinseo is committed to supporting sustainable innovation with a customer-centric approach, that also improves the end consumers’ lives. Learn more about our approach and process from Trinseo’s Pascal Lakeman and Rene Kruidenier:

Opus 12 started with the vision of "operating motor vehicles on fuels produced from previously emitted CO₂". Using water and electricity, preferably from renewable sources, CO₂ is broken down into chemical products and fuels, which in the past could only be produced from fossil energy sources. "With our technology," explains Nicholas Flanders, "the carbon footprint of the biggest emitters can be reduced significantly, and, at the same time, a new source of income can be generated with a material that was previously treated as a pollutant. The transformation of CO₂ currently enables us to produce sixteen different products that we use every day“.

The spectrum ranges from eco fuels to plastics. The technology developed by Opus 12 has a modular design and can thus be custom-tailored to the various areas of application. In future, the CO2-transformation technology will produce the inputs for production operations from within the same premises. This will enable companies to be self-sufficient, save on transport and start "The Next Green Thing". In a first pilot plant, Opus 12 together with an energy company from Southern California has already demonstrated how CO₂ can be transformed into methane.

Opus 12 offers a hardware solution that enables its customers to recycle carbon dioxide into valuable chemicals, materials and fuels. Opus 12's technology is transforming CO2 from waste to value while creating new revenue streams. They achieve this by using electricity and novel catalysts to turn CO2 and water into valuable chemical products.

Opus 12 is mainly active in the heavy industry, consumer goods, automotive, aviation, materials, chemicals and clean energy industries. Their focus is on use cases in business areas such as manufacturing, sustainability, chemicals, materials, innovation and operations. Founded at Stanford and Lawrence Berkeley National Lab, the company has built its first commercial device in collaboration with a world-leading system integrator and is now scaling to industrial capacity.

Visit Opus 12 and Daimler's Startup Autobahn online

Thought Leadership

Creating Ammonia-Free Solutions for the Building & Construction Industry

September 23, 2024

Thought Leadership

The Role of Scope 3 in Decarbonization Strategies

September 20, 2024

Thought Leadership

Article Written by Trinseo’s Jessica Hoffmann Appears in Pitture e Vernici European Coatings

September 17, 2024