Based on ten years of close partnership, our partner TRW/ZF Friedrichshafen, once again trusts Trinseo with the production of high-performance knee airbag covers produced with APIGO™ TPO.

APIGO™ TPO does not require painting and can be molded in color with specifically developed masterbatches enabling perfect color homogenization. The material also offers very good surface aesthetics and haptics, while featuring a very high scratch resistance.

Like all APIGO™ TPO grades, APIGO™ DP2476 offers easy processability with no visible sink marks or flow lines, and short cycle time. It can also be foamed to reduce weight with a specific foaming agent.

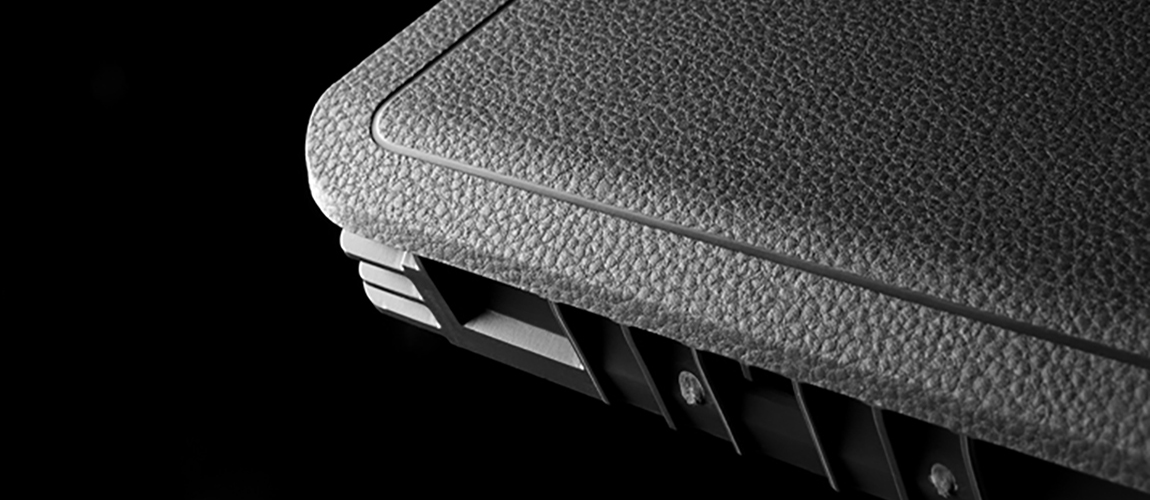

Knee airbag cover made with APIGO™ DP2476

The airbag system belongs to the most sensitive issues every OEM must take care about. Not only because of the safety of the people travelling in the vehicle, but also in regard of subjects like durability, resistance, and reliability of the whole system. APIGO™ DP2476 ensures compliance with the requirements of the ALKV L01 standard for airbag covers which includes the deployments tests at low and high temperatures from - 35°C to + 85°C, plus UV resistance.

According to TRW Core Engineers, there is another advantage of APIGO™ if you think about further capabilities of the material: “You only need one formulation for all airbag cover applications”. APIGO™ DP2476 and the slightly softer version APIGO™ DP2476 SHI offer the possibility to produce a variety of different airbag covers (knee-, passenger-, side-, thorax airbag covers) with the same material, without a need to adjust it depending on the specific geometry in question. So, this material solution not only is a perfect fit in performance, but also contributes to cost optimization.

APIGO™ DP2476 TPO on knee airbag cover

APIGO™ can not only help you reduce costs, but also support you in highly relevant challenges in the production process: It can solve the problem of hinge bending in airbag systems. Due to the way airbag covers - relatively long in shape - deploy, there can be irregular stress at different heights of the hinge – a problem which a very elastic material like APIGO™ DP2476 SHI can solve by allowing more flexibility along the whole hinge.

In conclusion TRW Core Engineers give a convincing résumé for this case study: „APIGO™ DP2476 SHI can be considered as a material of choice for all airbag cover applications where high performance and versatility must be accompanied with price competitiveness“.

Typical characteristics for APIGO™ TPO

Download the brochure highlighting Trinseo TPE Solutions for automotive applications.