KraussMaffei is a leading manufacturer of injection-molding machinery, reaction-process machinery, and automation. PANADUR is acknowledged as a supplier of innovative, functional coatings. Both partners invited us to KraussMaffei’s booth at the K 2016 trade show to produce an automotive interior decorative trim using KraussMaffei’s ColorForm technology together with Trinseo PULSE™ AX50 and PANADUR's polyurea paint. In the past, the interior trim was produced by an OEM in a traditional 2-stage process. The use of PULSE™ AX50 and polyurea enables KraussMaffei to produce the decorative element more economically and in better quality with one machine using one tool.

The positive experience of Daimler AG with PULSE™ AX50 drew the attention of KraussMaffei and PANADUR to our easy-flow PC/ABS resin. For the German premium OEM we had to develop a styrenics based resin material suitable isocyanate based lacquer coating in the ColorForm manufacturing process. The requirements for our PC/ABS substrate included:

With very low density and good heat distortion properties, PULSE™ AX50 provides optimum performance features to meet these requirements. Trinseo developed its innovative PC/ABS PULSE™ AX50 resin specifically for the production of high-gloss panel elements that need to withstand impacts while offering an aesthetic, high-quality appearance. The focus of development was on achieving optimum adhesive properties for polyurethane and polyurea paints. PULSE™ AX50 is ideal for time- and cost-saving multi-component injection molding as used in KraussMaffei’s advanced ColorForm technology.

The innovative production solution allows the surface material to be introduced direct into the cavity of the tool during the injection process. The thermoplastic basic body is coated while it is still in the mold, eliminating the need for painting or coating in what is otherwise a conventional second processing step. This results in less waste as well as in significantly lower material, process, and logistics costs for suppliers and OEMs alike.

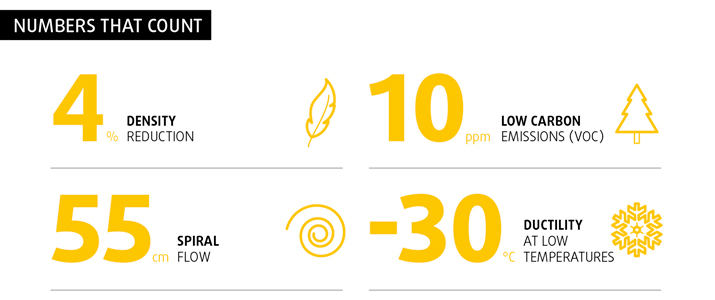

With a spiral flow of over 55 cm (260 °C, 2 mm, 1,800 bar), the outstanding flow characteristics of PULSE™ AX50 are the main reason for the excellent processing properties of the material. In combination with appropriate fillers, they also enable thin-walled, lightweight parts to be produced without forfeiting rigidity or dimensional stability, even with workpieces with a complex structure.

PULSE™ AX50 not only has excellent flow characteristics but also a very low density of just 1.09 g/ccm (ISO 1183/B). A significant reduction in component weight can be achieved when used in the KraussMaffei ColorForm process together with the polyurea surface coating system from PANADUR. Polyurethane and polyurea from PANADUR are also valued for their low density. It is possible to achieve very thin coatings with these easy-flow paints, enabling thinner walls than is the case when with polymethyl methacrylate, which is used in other coating processes.

There is a number of additional material characteristics that give our customers an advantage in the development and production of advanced lightweight construction applications.

PULSE™ AX50 demonstrates high impact resistance at room temperature as well as at temperatures as low as - 30°C. This is an important prerequisite for high resilience and durability for interior applications.

The adhesion properties of paint on a PULSE™ AX50 basic body remain outstanding even in the face of weather and temperature effects and UV radiation. Vehicle passengers benefit from low odor and VOC emissions (-10 ppm) whose values meet the specifications of all automotive manufacturers around the world.

The collaboration at KraussMaffei’s booth at K 2016 demonstrates that the individual, perfect coordination of high-performance materials and their customization to innovative manufacturing processes are the key to the successful automotive lightweight construction of the future. With its PC/ABS PULSE™ AX50 resin, Trinseo thus makes a significant contribution to the cost-efficient production of aesthetic and functionally advanced automotive plastic applications for its customers.

Download the PULSE™ AX50 Fast Fact Sheet.

For more information about this case or PULSE™ AX50 get in touch.