Trinseo offers more than 60 years’ experience in styrene-butadiene (SBR) latex research, development, and production. Being a pioneer in SBR, we also have renowned expertise in coating applications made with SBR latex. On this foundation, we have developed VOLTABOND™ adhesives for improved battery kinetics in Li-ion battery applications.

Our high-performance products bind the graphite and conductivity agent powder together and onto the current collector in a Li-ion battery. The VOLTABOND™ Binders family is aimed not only at meeting the increasing demand for Energy Stationary Storage (ESS) or Computer, Communication & Consumer (3C) applications, but also on EV batteries for the automotive industry.

VOLTABOND™ Latex Binders‘ features include:

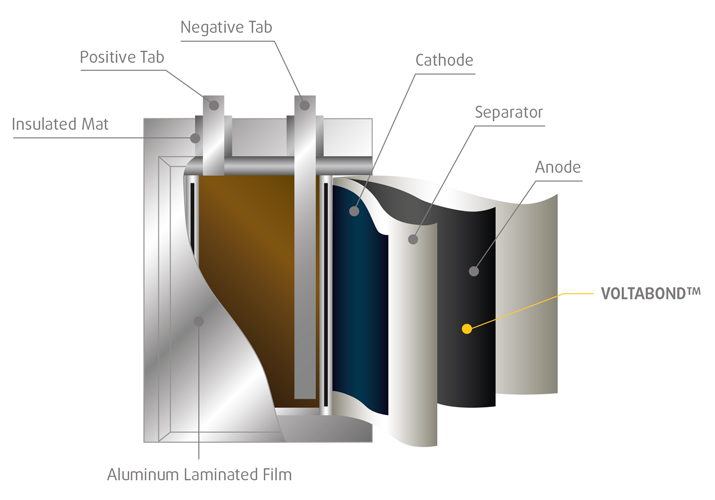

VOLTABOND™ Binder's position in the anode coating of a Li-ion battery to bind the graphite and conductivity agent powder together on the current collector (copper foil)

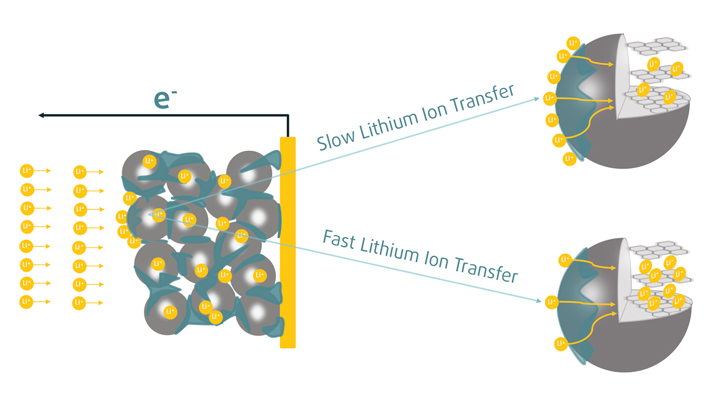

The latex particles form a film at the contact position of different graphite particles and exert a ‘point-to-point’ bonding effect. Therefore, the surface of a part of the graphite particles is covered by the latex film. The lithium-ion conductivity of the latex film is poor, so increasing the conduction rate of lithium-ions at the interface between the electrolyte and the SBR film will help improve the low-temperature performance of the battery.

Li-ion conduction rate between the electrolyte and the SBR film

The automotive business has become a global, multi-location industry. With our global development and production resources, we offer an international scale manufacturing and supply network to support OEMs and their suppliers. Trinseo's technology and innovation center in Rheinmuenster, Germany, includes the world‘s leading SBR synthesis R&D capabilities. Our professional Li-ion battery application laboratory in Shanghai, China, provides localized technical services and development support. This includes high expertise in Li-ion battery testing, such as:

Trinseo's VOLTABOND™ Binders product portfolio for EV battery applications

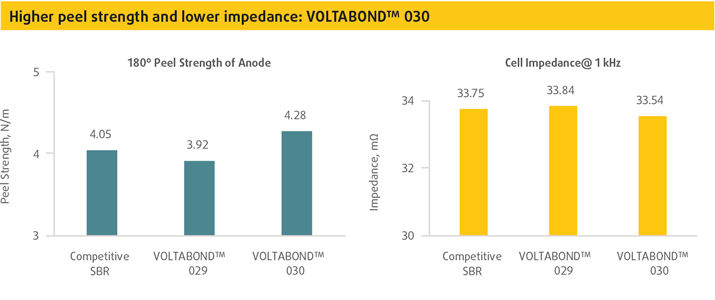

We evaluated the battery performance of VOLTABOND™ Latex Binders at the Korea Electronics Technology Institute (KETI) with competing SBR products as a reference. See some of the results:

VOLTABOND™ 030 – peel strength and impedance compared to VOLTABOND™ 029 and competitive solution

VOLTABOND™ 029 – C-rate performance compared to VOLTABOND™ 030 and competitive solution

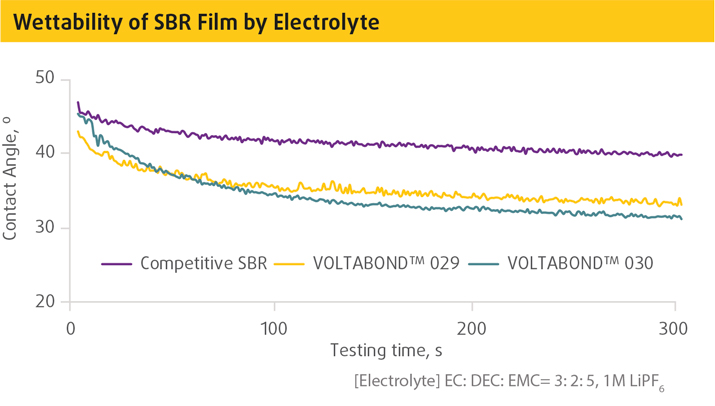

In comparison to the competitive SBR, the wettability of VOLTABOND™ 029 and VOLTABOND™ 030 film is much better, resulting in faster lithium-ion transfer at the electrolyte-SBR film interface.

Wettability of SBR Film by Electrolyte

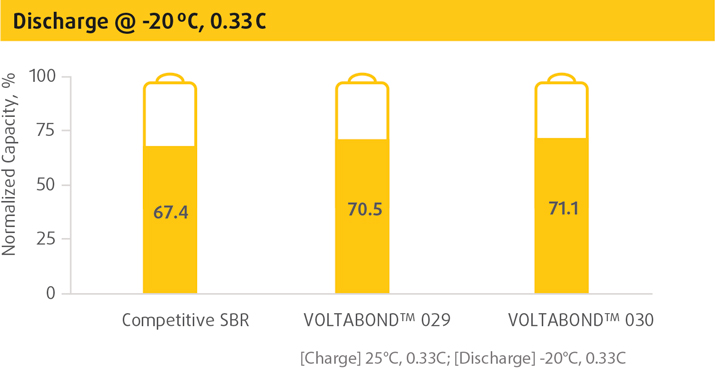

In addition, VOLTABOND™ 030 has a low glass transition temperature (-25 °C), so when using VOLTABOND™ 030 as the negative electrode binder, the battery -20 °C discharge capacity is effectively improved.

VOLTABOND™ provides improved discharge capacity

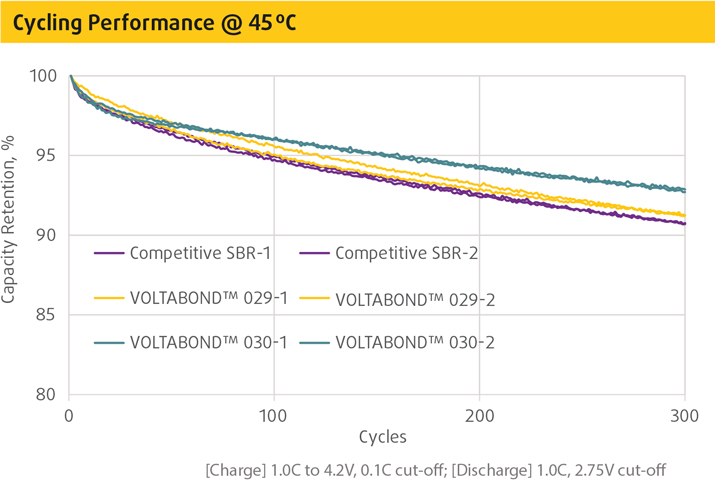

The cycling performance of VOLTABOND™ 030 is much better than the competitive SBR. The capacity retention is 2 % higher than the competitive SBR after 300 cycles at 45 °C.

VOLTABOND™ 030's higher capacity retention

We stand ready to support customers as a pioneer and global leader in SBR latex In a highly challenging environment, with increasing availability of Li-ion EV batteries. A team of Trinseo experts, including Polymerization R&D, Application Development, Technical Service and Commercial team, as well as a battery consultant, ensures that we can offer SBR latex binders with outstanding performance when compared to the competition.

Get in touch for more details and let's start a conversation on how we can support your business with VOLTABOND™ Latex Binders solutions for high-performance energy storage.

Thought Leadership

Creating Ammonia-Free Solutions for the Building & Construction Industry

September 23, 2024

Thought Leadership

The Role of Scope 3 in Decarbonization Strategies

September 20, 2024

Thought Leadership

Article Written by Trinseo’s Jessica Hoffmann Appears in Pitture e Vernici European Coatings

September 17, 2024